COLO-Your Source For Powder Coating System

Surface Finishing Technology

since 2009Call us Today!

+86-133-96517035

|

Model

|

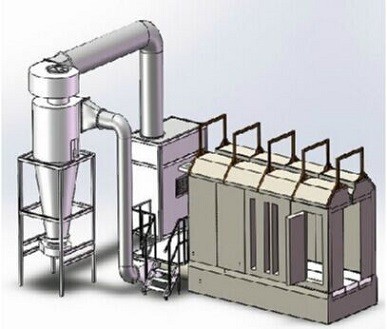

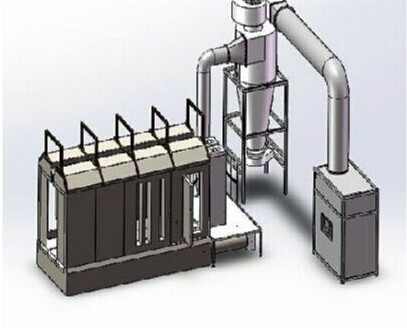

COLO-Mono Cyclone

|

|

Working Dimension (mm)

|

800width x 2000 height x 6000 depth mm

|

|

Weight

|

4000kg

|

Voltage | 380V/220V. customized as local. |

Power supply | Electric |

Nominal power | 15kw |

Frequency | 50-60Hz |

Filters | Polyester, 32pcs |

Filter cleaning system | Pneumatic |

Booth Material | Wall: Stainless Steel |

Cyclone Material | Stainless Steel |

Find out more about our standard Size powder coating equipment Kits (Includes Powder Coating Booth, Electric or Gas Powder Oven, and Optional Gun) or send us your enquiry now to find out what we can do for you.