Surface Finishing Technology

since 2009Call us Today!

+86-133-96517035

Powder coating is an exciting method for finishing products through the application of tiny dry particles. For this reason, powder coating is sometimes referred to as “dry painting”. Rather than applying the paint in a wet state, we simply use a modern, clean, and efficient electrostatic powder coating process that relies on the attraction between charged particles that are fused together. This process is generally less prone to mistakes than traditional wet spray. Further, powder coating does not require the use of harmful chemicals.

POWDER SPRAY SYSTEM

This is heart of the powder paint shop, Normally an electrostatic powder spray system is usted, this sprays electrostatically charged powder into the spray booth where the articles to be coated are hung. Electrostatic forces provide a uniform and consistent coating quality.

NEW vibrator powder coating systems CL-161S

Advantage:

Reservar 20 programma of manual systems

360 degree moving trolley

Durable spray gun

Electrical data

Power range 220V/110V

Frequency 50HZ /60HZ

Temperature range in use -10 ℃+50 ℃

Powder Gun

Gun weight: ……………… 500G

Rated output voltage ……… 24VDC

Input voltage …………… - 200kv

Maximum output current ……… 180Ua(max)

Maximum output voltage………… 0-100KV ( adjustable)

Maximum powder injection :……… 600g/min

Polarity ……………… negative (-)

Pneumatic data

Maximum input-air pressure ………….. 10kg/cm

Optimum input-air pressure…….. 6kg/cm

Minimum input-air pressure …… 4kg/cm

Maximum water vapor content or compressed air ….. 1.4g/N m3

Maximum oil vapor content of compressed air …….. 0.1ppm

Maximum compressed-air consumption……… 13.2 m3/h

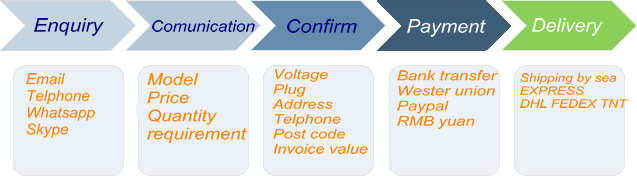

How to purchase with HICOLO?

Find out more about our standard Size powder coating equipment Kits (Includes Powder Coating Booth, Electric or Gas Powder Oven, and Optional Gun) or send us your enquiry now to find out what we can do for you.