Surface Finishing Technology

since 2009Call us Today!

+86-133-96517035

With small size, light weight and excellent, easy to use, insulation performance characteristics.

Seven channels painting temperature tracker for compressor painting line

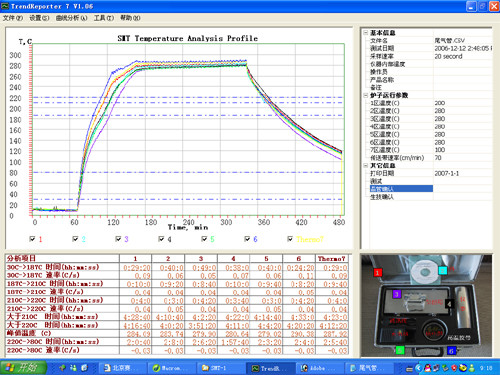

The temperature tracker mainly used such as cars, motorcycles, appliances, aluminum extrusions, furniture, cabinet, elevator, highway guardrail, auto parts, motors, compressors, valves, piping, mechanical, sanitary ware, temperature quality assurance within the kitchen, garden facilities, shelves, lamps, lights, containers, cans, batteries, electronics and other industries a variety of baking ovens and bake coatings, curing process, process optimization and equipment improvements in testing, to improve production efficiency, ensure product quality, operating cost savings to meet the purpose of environmental protection requirements.

Cabinet coating production line

Sampling methods

1. Continuous (FIFO), 2. Stopped working after filling (after fill stopped working)

Sampling rate

The sampling period is 0.04s, 0.1s, 0.2s, 1s, 2s, 8s, 12s, 20s, 40s, 60s to 8h

PC requires Microsoft Windows 2000, NT, XP

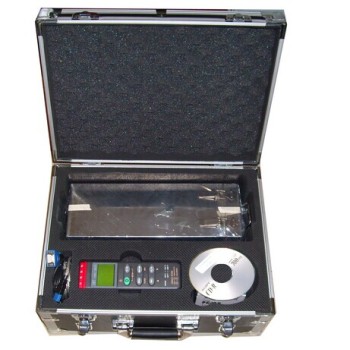

Standard configuration * seven-channel temperature tracker

* 7 1.75 meters temperature probe

* Computer connection cable

* Data processing software, data analysis software

* Stainless steel incubator, including suspension handle

* Operation Manual

Find out more about our standard Size powder coating equipment Kits (Includes Powder Coating Booth, Electric or Gas Powder Oven, and Optional Gun) or send us your enquiry now to find out what we can do for you.